Smart Monitoring for

Indian Factories.

A plug-and-play IoT platform built for the realities of Indian shop floors. Monitor production, energy, and downtime in real-time — no complex IT required.

Built for Industrial Reality

Backed by the pioneers of INDIA_SMART_MFG digital infrastructure.

DPIIT Recognition

National recognition under Startup India for industrial engineering innovation.

Industrial Pilots

Successfully transitioned from prototypes to live deployments in major manufacturing hubs.

Commercial Deployment

Actively monitoring production lines for leading Indian automotive manufacturers.

Platform Scalability

Full-stack IoT architecture validated for high-fidelity real-world manufacturing data.

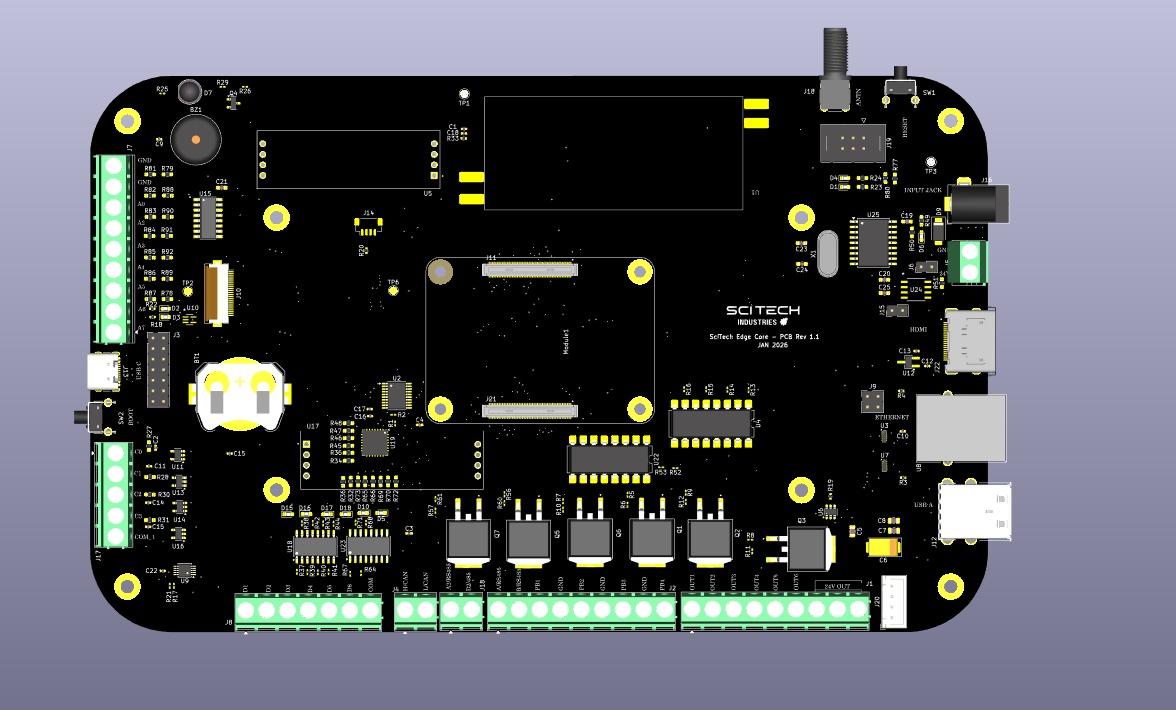

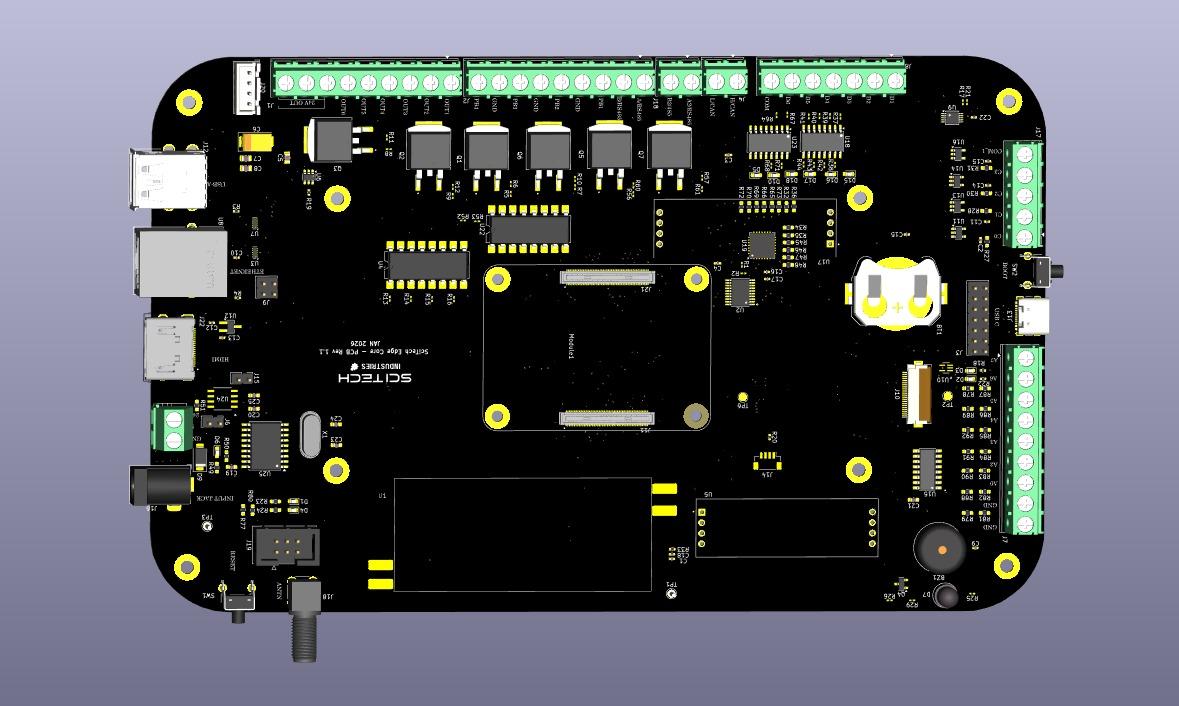

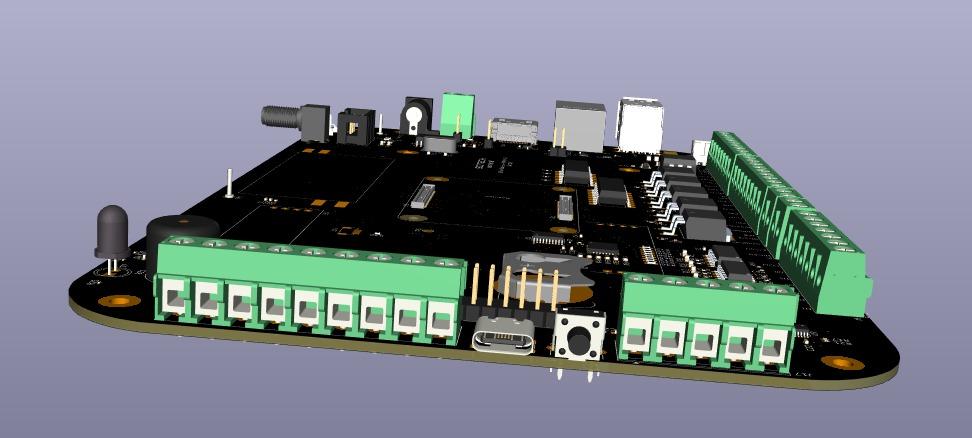

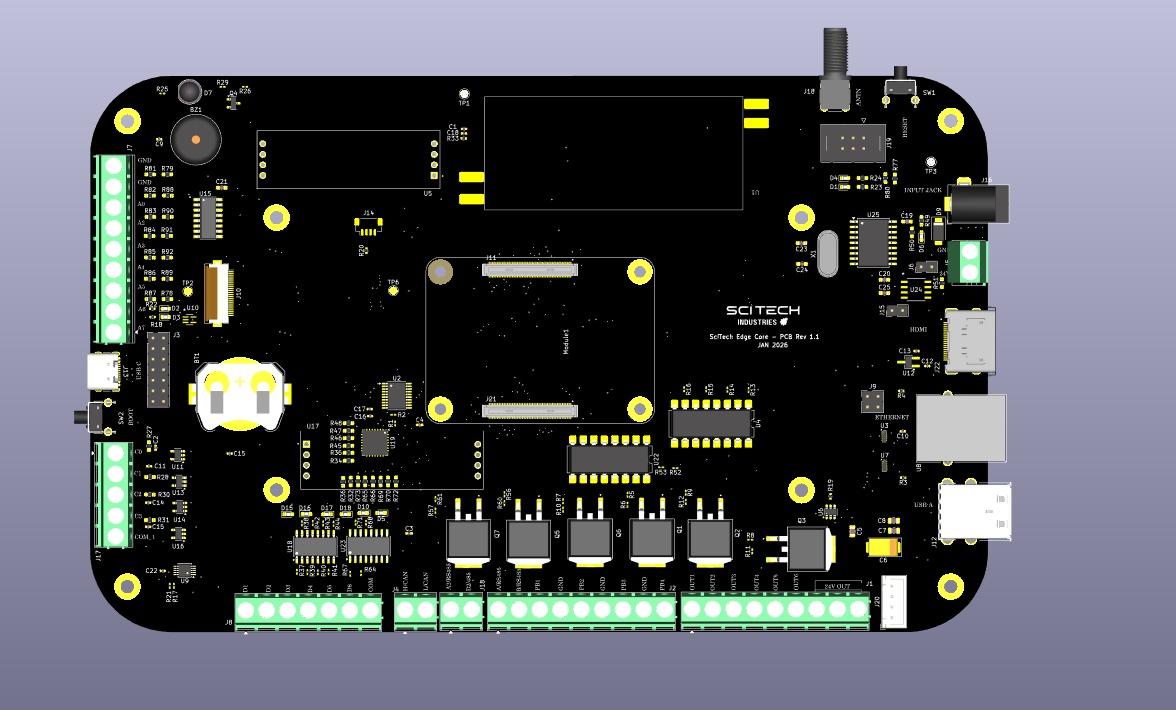

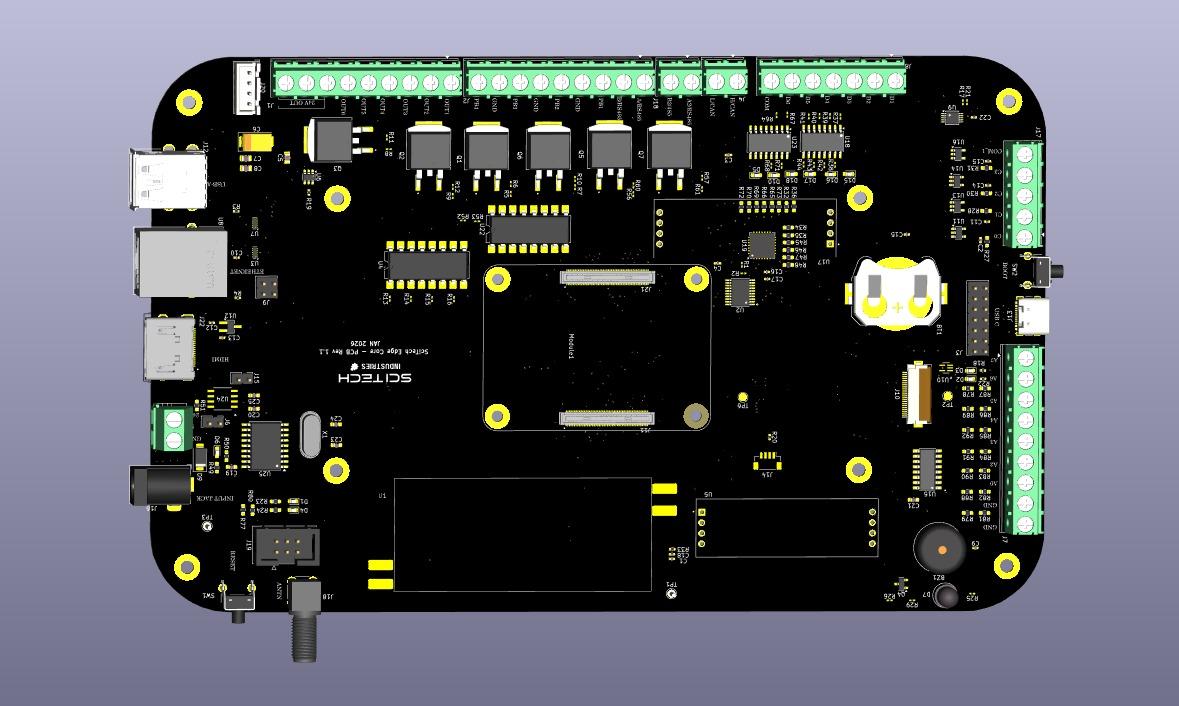

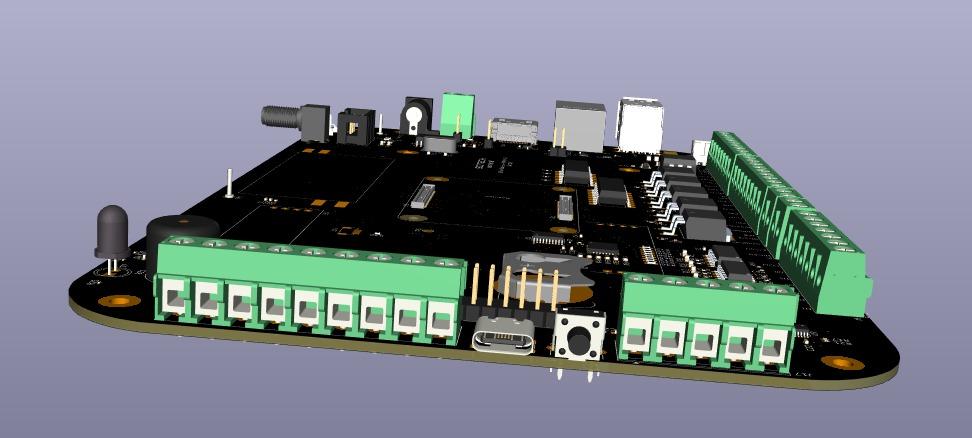

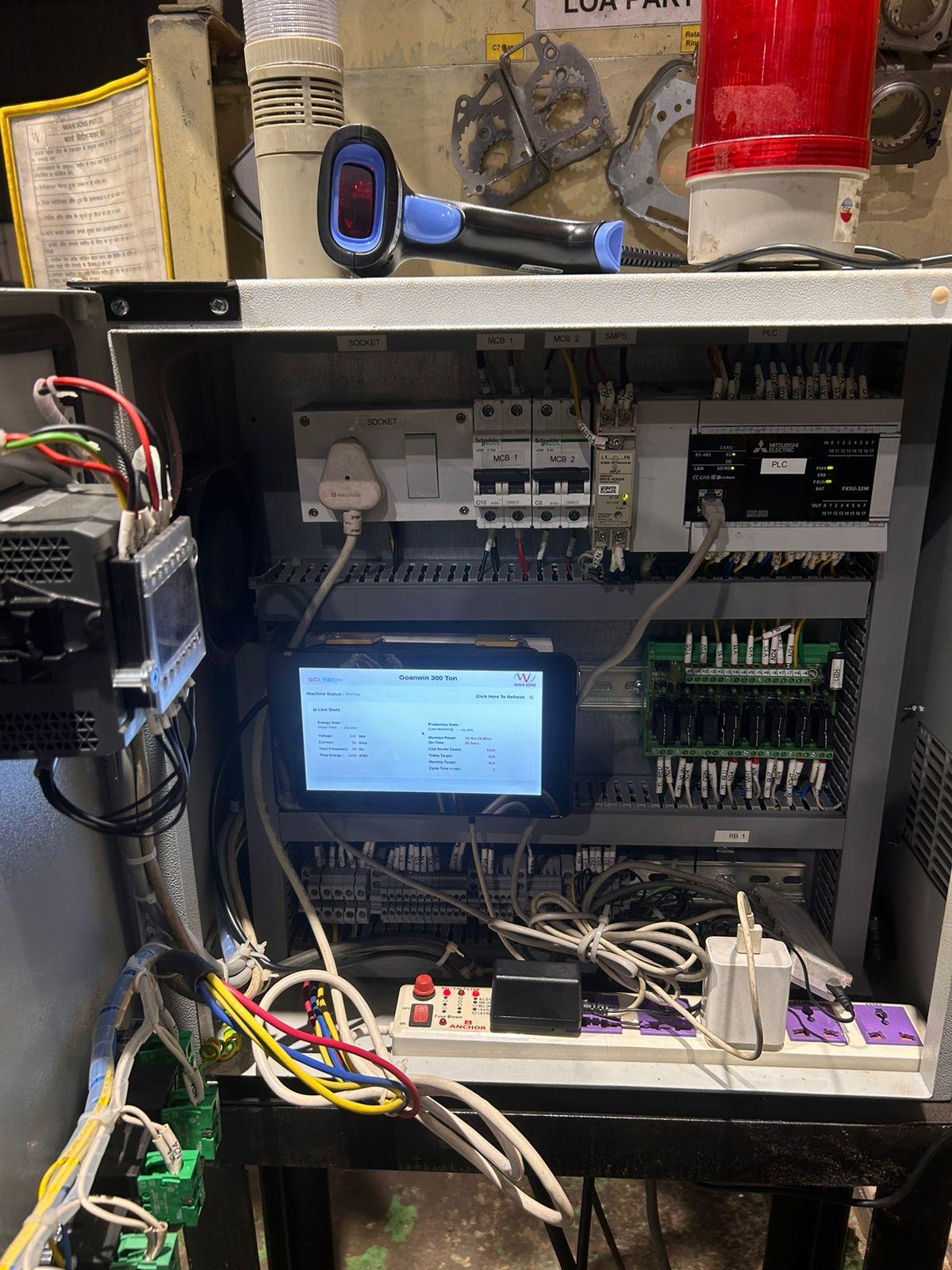

Industrial-Grade Edge Hardware

We don't just code software. We architect the Physical Layer—designing our own hardware to guarantee 100% data integrity in the harshest shop-floor environments.

SciTech Edge Core — PCB

Precision-layered signal processing for high-fidelity data.

Ruggedized Enclosures

Military-standard protection for industrial shop floors.

Scaled from Single Pilots to Enterprise Fleets.

Manual Reality.

Unseen Waste.

UNITS: CRANE_OP_04

STATUS: TOOL_CHANGE_IN_PROGRESS

LATENCY: 42m_ELAPSED

Ground-shot from Wahisons Private Limited. A breakdown occurs, the machine stops, and a crane is manually deployed for a tool change.

This breakdown was captured by our MVP Installation, providing the first real digital audit of shop-floor downtime.

Unplanned Downtime

Machines stop unexpectedly. Root cause identification takes hours, delaying shipments and killing OEE.

Industrial Blind Spots

Zero real-time visibility into shop floor cycles.

Manual Paper Logs

Inaccurate paper records lead to data delays and human error.

Reactive Maintenance

Fixing machines only after they fail. No horizontal deployment or predictive insights.

"When machines stop without data, profit leaks silently. We capture every micro-stop to ensure it never happens again."

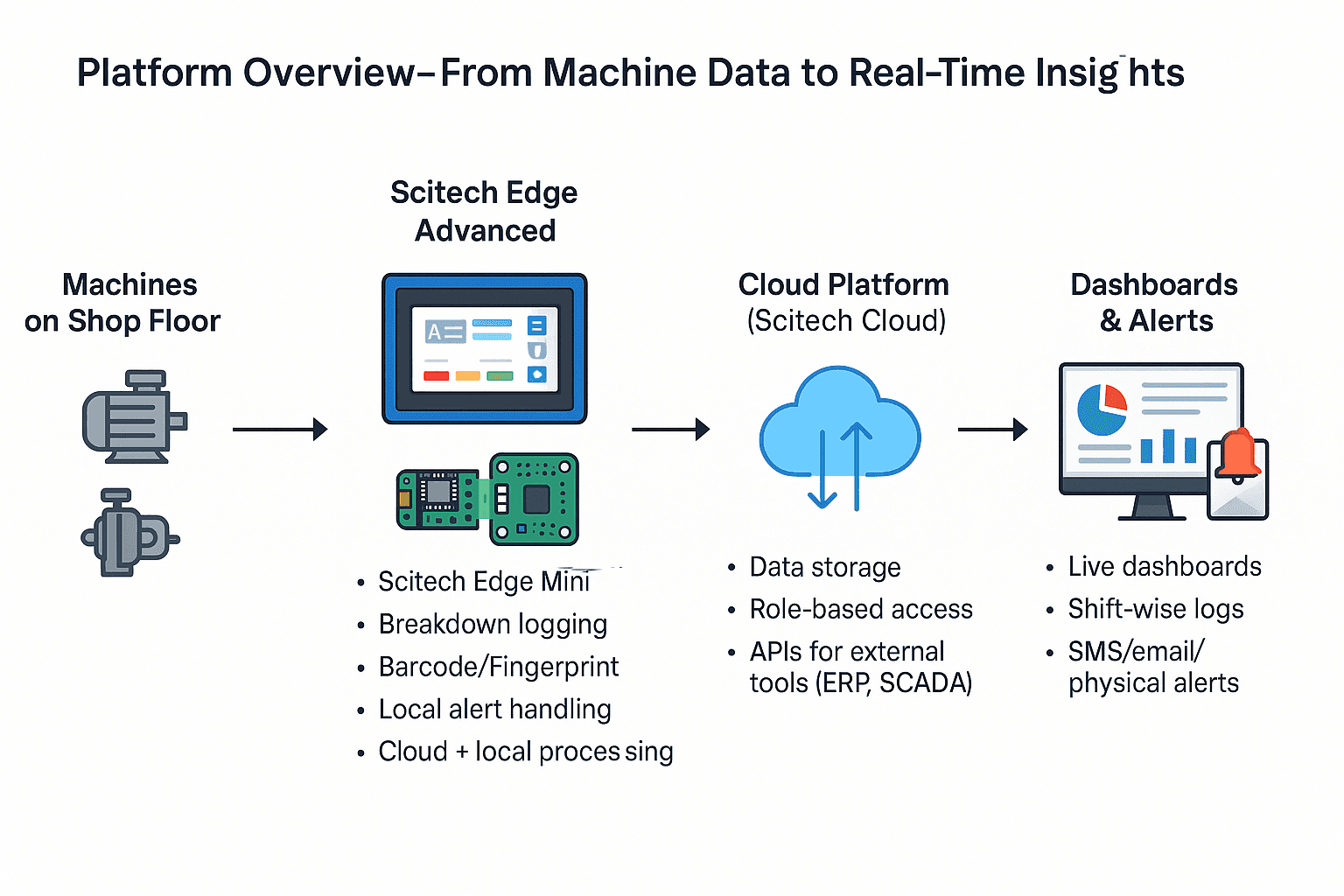

From Machine Signals to

Actionable Intelligence.

A zero-friction, plug-and-play ecosystem designed for the unique demands of Indian Manufacturing.

Scitech Edge

The neural link to your shop-floor assets.

- Non-intrusive machine integration

- Real-time sensor & cycle capture

- Industrial-hardened firmware

- End-to-end payload encryption

Scitech Cloud

Central hub for factory-wide intelligence.

- Universal Live Dashboard access

- Dynamic alerting & breakdown matrix

- Automated OEE & Production reports

- Deep historical big-data analytics

Protocol_Flow

Instant Response

Maintenance teams react in minutes, not hours, with real-time breakdown alerts.

Auto-Logging

Automated cycle counting removes human error and recovers lost shift time.

Full Visibility

Digital shop floor audit accessible from any device, globally.

Predictive Ops

Transition from reactive fixes to data-backed predictive maintenance cycles.

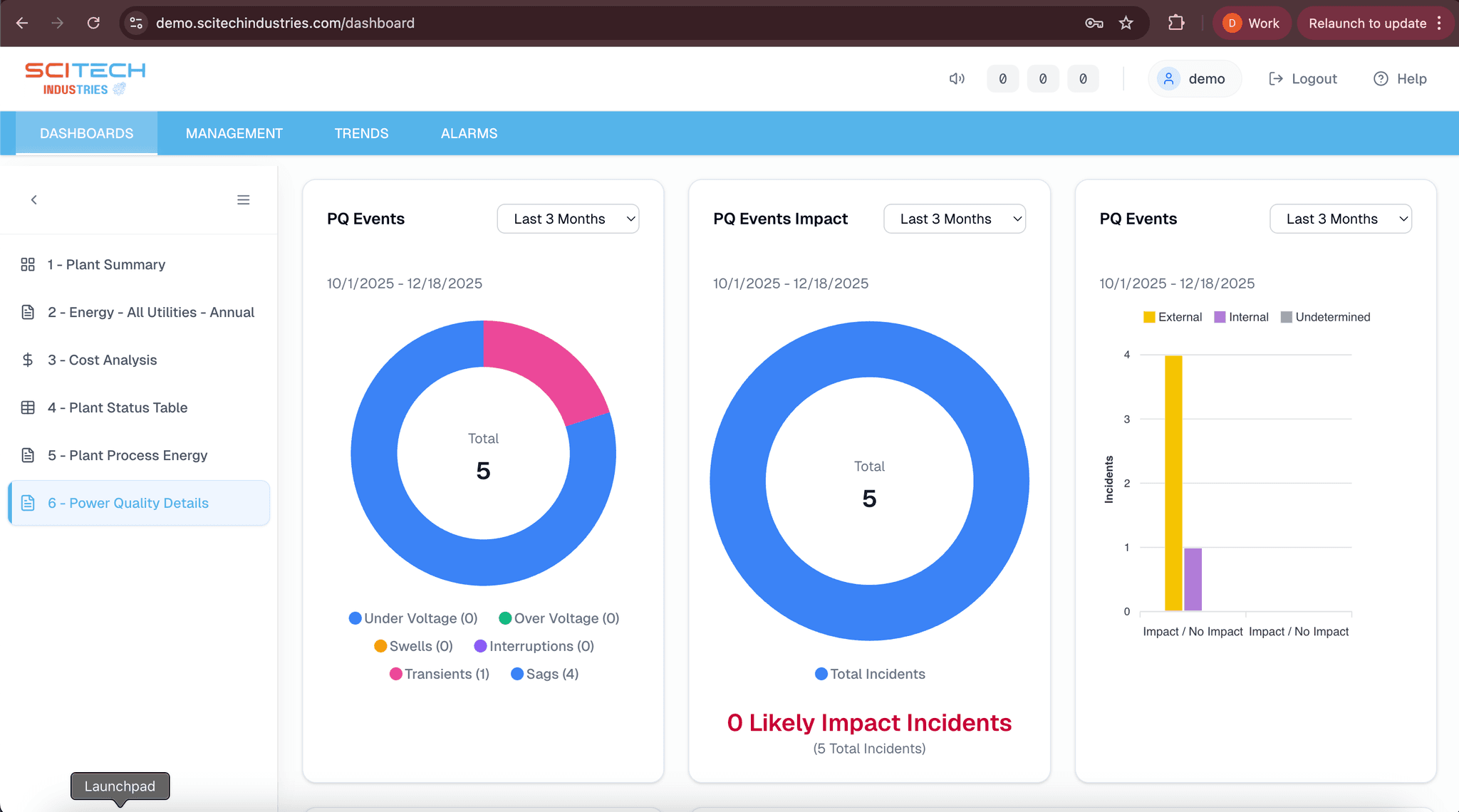

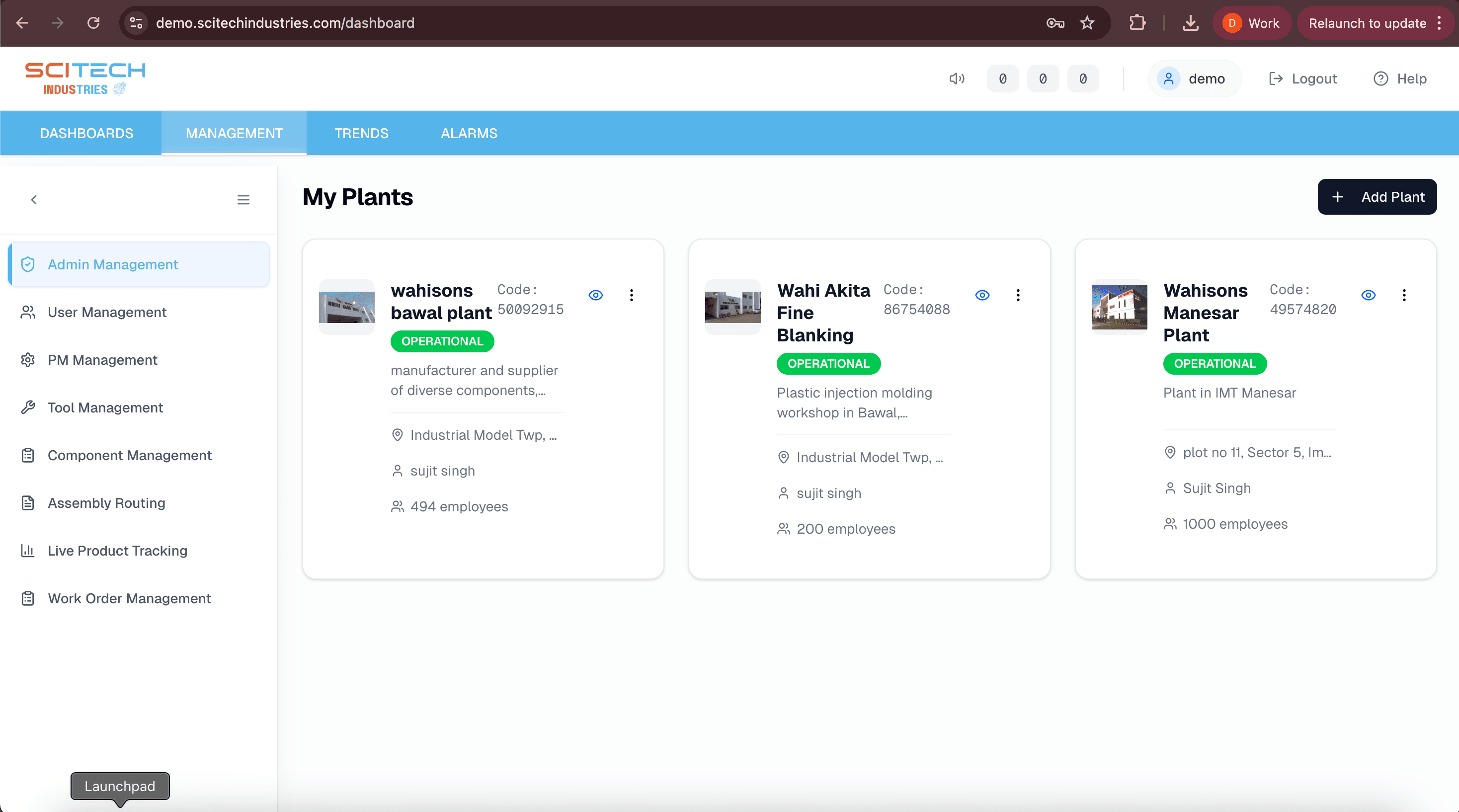

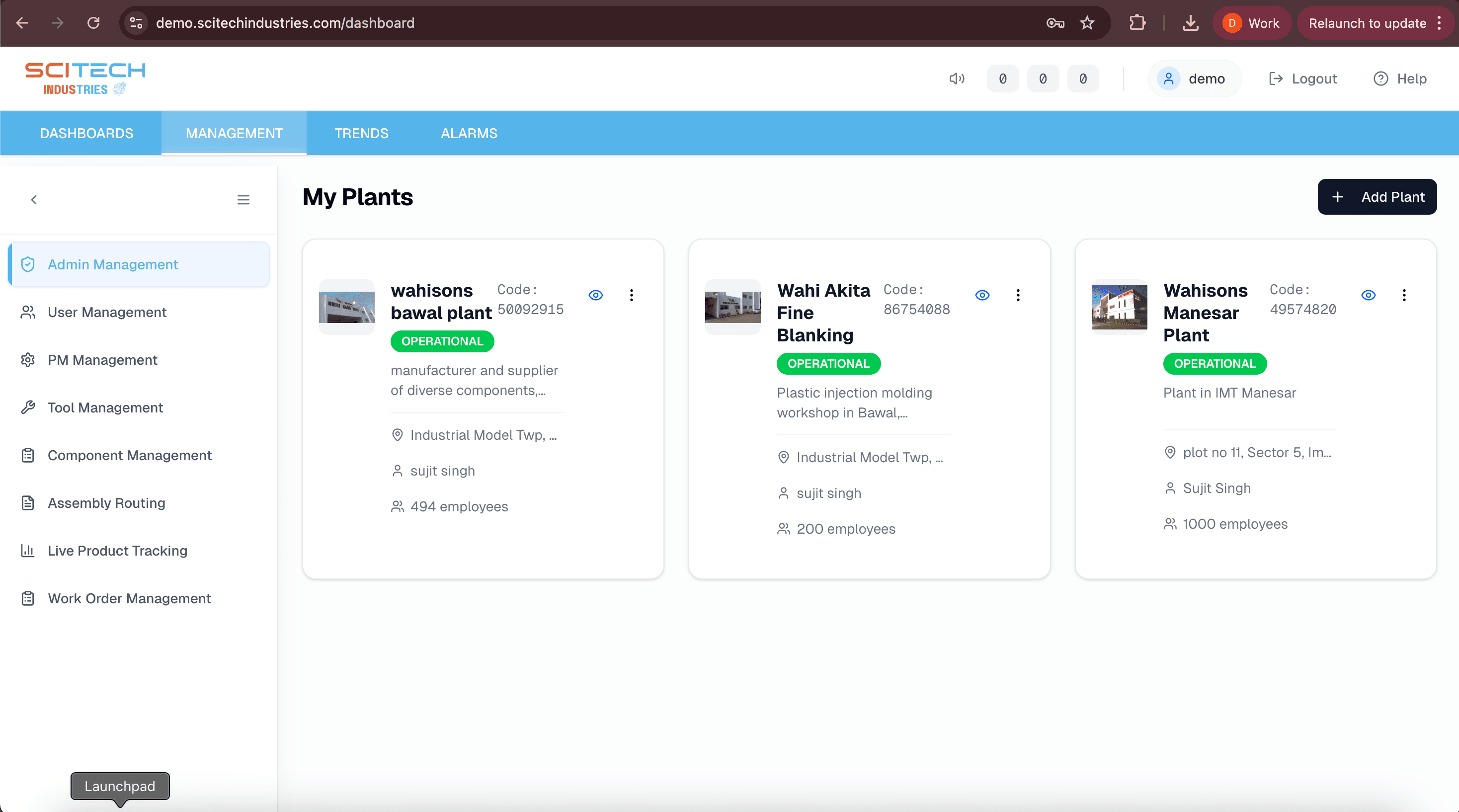

Command Center for

Autonomous Operations.

Once deployed, Scitech provides a unified holographic viewport into your entire industrial infrastructure—available Anytime, Anywhere.

Uptime Analytics

Monitor machine states (Run/Idle/Stop) instantly across the floor.

Breakdown matrix

Instant notifications when downtime occurs to minimize losses.

Energy Interface

Track power consumption per machine to optimize operational costs.

OEE Forensics

Analyze production trends, cycle times, and output over shifts.

Instant Response Matrix

Autonomous alerts are prioritized and pushed directly to authorized team terminals, allowing for immediate mitigation before small anomalies escalate into total downtime.

"With centralized intelligence, plant teams move from Reactive Fixing to Predictive Governance."

Applied Industrial

Utility Frames.

Scitech protocols integrate directly into the manufacturing DNA—optimizing for Efficiency, Transparency, and Scale.

Downtime Analytics

Real-time machine availability tracking to isolate micro-stops and productivity leaks.

Breakdown Response

Direct-to-terminal maintenance alerts, reducing mean time to repair (MTTR) by up to 40%.

Utility Forensics

Per-asset energy auditing to identify phase imbalances and consumption anomalies.

Support Systems

Data-driven maintenance intervals based on actual machine runtime, not calendar days.

Multi-Plant Sync

Unified visibility across geographical zones, syncing local line data to global headquarters.

Access Matrix

Permissions defined by operational sector requirements.

Built on Real

Factory_Experience.

Scitech wasn't born in a lab—it was forged on the shop floor. Every line of code and every wire in our MVP solves a real-world visibility breakdown.

- MS::PLT_01Industrial pilots completed in diverse environments.

- MS::COM_01First commercial deployment actively running.

- MS::OPS_24Live production environments monitoring 24/7.

- MS::L7_SYSFull Edge + Cloud platform in active use.

- MS::BI_INOngoing data-driven operations delivering insights.

"Proven foundation. Industrial scale. Scitech is ready."

Start Your

Digital Pulse.

Join the fleet of Indian manufacturers transforming their shop floors with Scitech. Get Real Visibility in 24 hours.

Zero IT-Friction

Up and running in 24 hours.

Secure Mesh

Enterprise-grade industrial encryption.

Instant Yield

Live visibility into production losses.

Direct_Uplink

Geom_Hub

Gurugram, NCR Hub